Process Manufacturing |

Discrete Manufacturing |

|---|---|

Process manufacturing relies on creating formulas or recipes to produce a product |

Discrete manufacturing assembles parts in a prescribed process to produce a distinct item |

Process industries make products in bulk quantities, such as pharmaceuticals, food and beverage, and paints |

Discrete manufacturers produce or assemble component or finished products recognized by serial numbers or labeling products |

Products cannot be broken down into constituent parts |

Products cann be broken down and dispose constituent parts |

Uses formula or recipe |

Uses a bill or materials (BOM) |

Process manufacturing offers many advantages to businesses, including improved efficiency, cost savings, increased scalability, and higher-quality products |

Discrete manufacturing offers advantages in terms of flexibility, efficiency, quality control, customization, and speed |

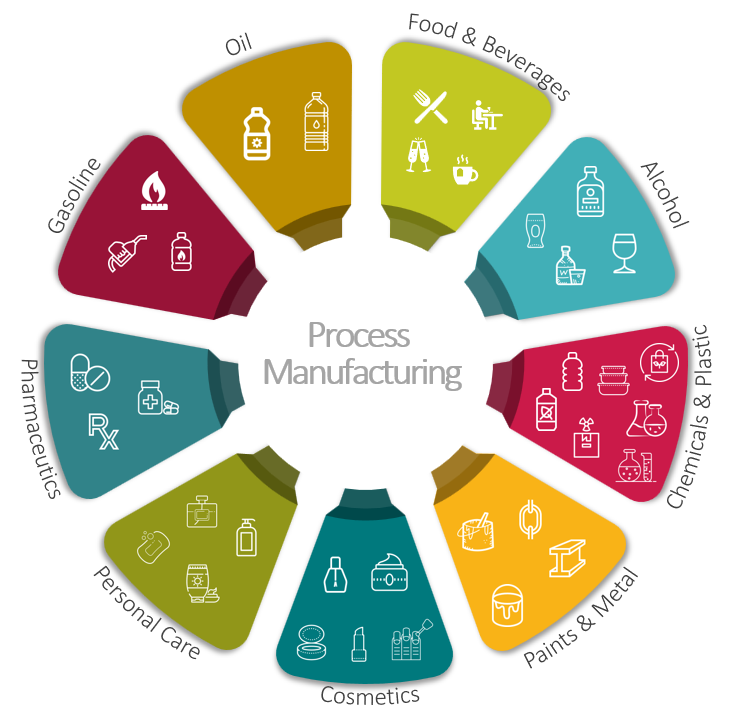

Examples of Process Manufacturing are Food and beverages ,Refined oil, Gasoline, Pharmaceuticals, Personal care products, Cosmetics, Specialty chemicals, Plastics, Metals, Paints, Alcohol |

Examples of discrete manufacturing are Automobiles, aeroplanes, Medical devices, furniture, Apparel, toys, Electrical , Communication and electronic devices |

MES for process industries must provide material management capabilities that not only track these raw material characteristics but also the characteristics of intermediate and final products as a set of ingredients undergoes conversion through the process steps.

MES for process industries is the need for both formula management software and spec management software. A single specification for a product – for example, a unique and recognizable taste for a company’s orange juice – may require different formulations from region to region to account for the differences in orange sugar content and flavor, which depend on the variety, growing region, and growing season.

Key features of MES for discrete manufacturing include:

✓ Adaptability and Customization to New Formulas/Recipes

✓ Management of Co-Products and By-Products

✓ Supply Chain Optimization, Cost Tracking

✓ Tracking of Shelf Life

✓ Instant access to production documentation

✓ Real-time shop floor visibility

✓ Enhanced manufacturing operations and WIPs (work-in-progresses)

✓ Quality Management and market Compliance

✓ Supports Different Measurement Units

✓ Able to Track and Trace Lots

Modern MES for process industries allows process manufacturing companies to implement highly efficient and flexible operations while also ensuring the highest quality in their finished products.

Additional benefits:

✓ Shorter cycle times and greater on-time deliveries

✓ Less demand on limited resources

✓ Assurance that production does not outpace maintenance requirements

✓ More efficient movement, storage, and tracking of materialss

✓ Visibility of current and historic manufacturing operations performance

✓ Decision support to correct and improve in-process functions

✓ Streamlined compliance and reduced cost of quality