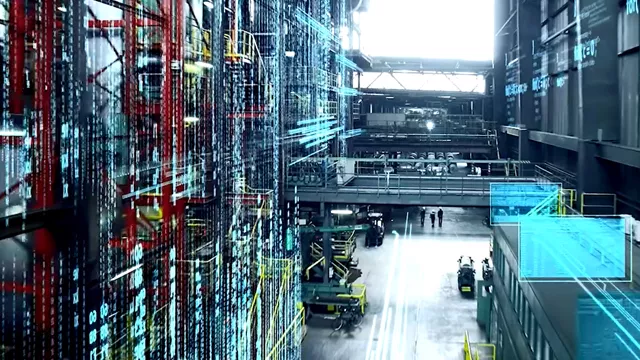

Opcenter Execution Electronics (formerly known as “Camstar Electronics Suite”) is a full digital manufacturing solution for the electronics industry. It addresses PCB, mechanical assembly and box-build production. The solution, based on direct connectivity to machines and production lines, includes manufacturing execution, quality management, planning and scheduling, material management and manufacturing intelligence.

Opcenter Execution Electronics integrates the Siemens Digital Industries Software portfolio and expands the digital thread throughout the entire design to manufacturing flow. Electronics manufacturers can change and reconfigure manufacturing and quality processes at the speed required to meet increased customer demand and quality requirements. Electronics manufacturers are realizing faster NPI and time to market, while improving their ability to compete in a rapidly changing, consumer-driven marketplace.

Maximize profitability, flexibility, quality, and compliance in manufacturing by digitally managing the rules and information for all operational activities and plant events in real-time.

We collect & consolidates information technology with operational technology from your existing equipment and systems, enabling you to make data-driven decisions and automate almost everything.

Manufacturing Intelligence creates a complete view of manufacturing operations. This end-to-end visibility can provide quality control at each point in the product lifecycle.

Data Analytics

Providing PCB manufacturing executives, line managers, and manufacturing engineers with crucial information needed to deliver quality products on time. |

Data Collection

Our data collection capabilities enable you to obtain operational production data that is associated with Production |

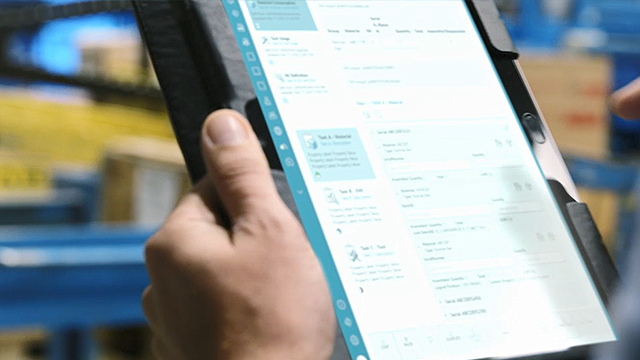

Production Dispatching

Sequencing of manufacturing operations and WIP driven by task management makes it easy for operators to perform operations |

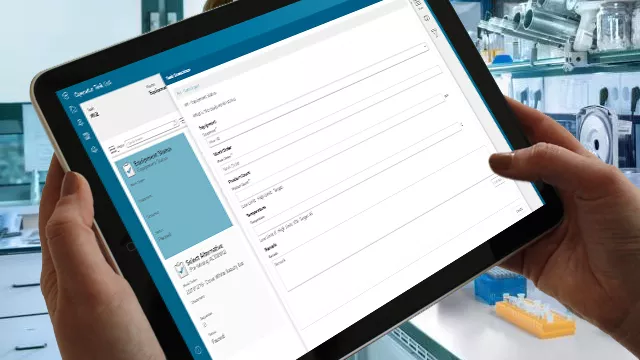

Document Maintenance

Our Software document control solution provides the ability to control records and forms that are maintained with the Production & Engineering |

User Management

Siemens MES User Management capabilities provide the status of the user, attendance , Training tracking, as well as the ability to track production support functions performed by user |

Operations Management

Siemens MES Software Management capabilities, user can track resource usage based on elapsed and usage time and production quantities, based on predefined limits, ensure that production does not outpace maintenance requirements |

Inventory and Material TrackingSiemens MES solutions provides the ability to manage and track the movement and inventory of materials, in-process items, and finished products, as well as the transfers between and within work centers |

Operations & Scheduling

Siemens MES delivers operations and detailed scheduling capabilities that provide the sequence and the timing of operations based on priorities and production rules |

Performance Analysis

Siemens MES solutions provide up-to-the-minute reporting of actual manufacturing operations along with a comparison to historic and expected results |

Process & Data Management

Siemens MES solutions monitor production processes and provide decision support to operators for correcting and improving in-process functions |

Production TrackingSiemens MES production tracking capabilities provide the status of production and the disposition of work, including the capability to record the production information allowing forward and backward traceability of components |

Quality Management

Ensure end-to-end quality management across your manufacturing process. Greater process quality control improves quality consistency. Focus on prevention to streamline compliance and reduce the cost of quality |

Resource Control

Siemens MES solutions enable you to manage all relevant resources related to manufacturing operations. These resources include machines, tools, labor skills, materials, procedures and many other entities |