PLM-MES-ERP Integrations

PLM, ERP, and MES are all vital to effective manufacturing, and the ability to integrate seamlessly between them can make or break a company

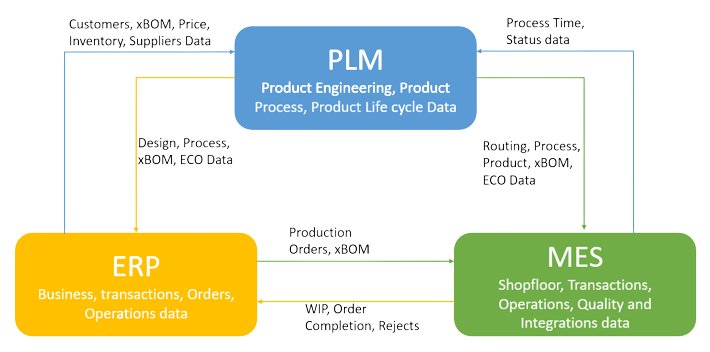

As we move towards digitalization, more integration is necessary between core enterprise systems – PLM, ERP, and MES. Market expansion and added technologies result in companies updating and optimizing their systems. For example, companies can choose to view business process use cases in a holistic way across an enterprise apart from business applications. This reduces costs, decreases rework, and streamlines workflow

PLM-MES-ERP Integrations

Product lifecycle management (PLM) is the process of managing the entire lifecycle of a product from inception, through engineering design and manufacture, to service and disposal of manufactured products. PLM integrates people, data, processes, and business systems and provides a product information backbone for companies and their extended enterprise.

Enterprise Resource Planning (ERP)

Enterprise Resource Planning (ERP) is used by companies to manage planning and execute business processes such as accounting, project management, purchasing and procurement, production facility planning, inventory levels and many other supply chain activities. An ERP offers scalability and room for expansion as a business grows and adjusts to market trends. There are industry specific ERP systems as well as open-source ERPs and each has its own niche in the market. Additionally, most ERPs have a robust API for integration benefits, helping to normalize integration. Looking for integration capabilities ensures your systems for future viability.

Manufacturing Execution Systems (MES)

A manufacturing execution system, or MES, is a comprehensive, dynamic software system that monitors, tracks, documents, Data collection, Quality Data processing and controls the process of manufacturing goods from raw materials to finished products

Manufacturing Execution Systems (MES) is your system to connect and manage the planning and execution of your manufacturing functions at the plant level. Additional details for MES include work instructions, routings and other process definitions required for the execution phase of the process. The most recent model shows the relationship between business strategy, enterprise, and shop floor operations

End items produced will have unique attributes related to production execution. The same product could be produced on different production lines within a plant, or produced at a different plant, or even produced in a different country. Inventory consumption happens in MES, and each of the consumed items may have uniqueness to them, providing the details to build a digital twin

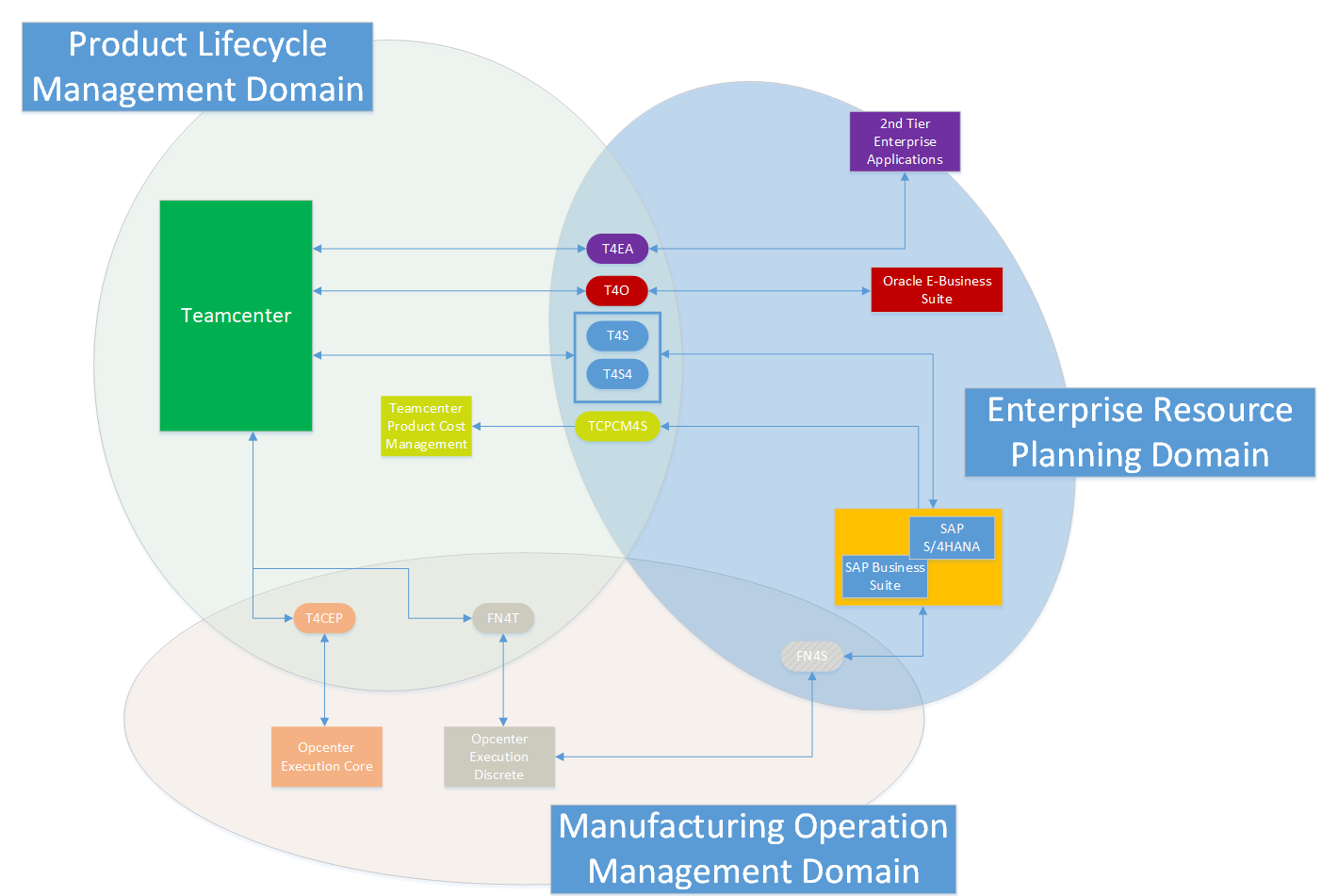

Active Integration Solution Overview

SIEMENS Teamcenter Gateway solutions T4CEP, FN4T, T4S,T4S4 & T4EA

- Active Integration enables full bi-directional information exchange, making the right data available anywhere across the enterprise

-

Teamcenter Gateway Solutions support the transfer of data like Parts, Documents, Changes, all types of BOMs, Bill of Processes (BOP) etc...

from Teamcenter PLM system to any other external systems such as ERP, MES and other enterprise applications - Data integration functionality includes bi-directional data transfer and data synchronization between enterprise applications

-

Teamcenter Gateway solutions have a full suite of administrative tools to ensure that all aspects of the Gateway software are always up

and running and are scalable to support all your enterprise needs

Benefits of using Opcenter Connect

Opcenter Connect expedites central solution deployment to tightly connect business and manufacturing systems.

Accelerate deployment

Facilitate rapid access to systems, machines and/or processes.

Eliminate dependencies

Build the digital thread independent of specific products or applications.

Maximize data flow efficiency

Automatically apply data normalization and standardization.

More value from your IT investment

By consolidating and enhancing Opcenter connectivity, Opcenter Connect reduces project effort and risk. It also enables end-to-end message processing and diagnosis. Opcenter Connect integrates Opcenter systems with enterprise resource planning (ERP) systems, manufacturing systems with cloud intelligence systems, Opcenter systems with manufacturing shop floor devices or tools, and much more.

Numerous deployment options

Opcenter Connect is compatible with almost all solutions, including distributed solutions. Its components are scalable and support a high-availability architecture.

Eliminate manual process errors

Opcenter Connect provides up-to-date information gathered through tightly connected business, manufacturing, quality and shop floor systems. As a result, you gain control over cumbersome, error-prone manual processes.